Manual override is a mechanism enabling manual control of automated systems‚ crucial for overriding automated functions in emergencies. It ensures human intervention‚ safety‚ and system reliability.

1.1 Definition and Purpose

A manual override is a mechanism that allows human intervention to bypass automated systems‚ enabling direct control in critical situations. Its primary purpose is to ensure safety‚ reliability‚ and flexibility by providing an alternative to automated processes when necessary. This feature is essential in systems requiring emergency interventions or adjustments‚ ensuring human oversight and decision-making capabilities. It is widely used across industries to address errors‚ unexpected conditions‚ or the need for precise control beyond automated capabilities.

1.2 Historical Development

The concept of manual override dates back to early automation systems‚ where human intervention was necessary to correct errors or adapt to unforeseen conditions. Initially‚ it involved simple mechanical switches or levers‚ allowing operators to take control from automated processes. Over time‚ advancements in technology integrated electronic and software-based solutions‚ enhancing reliability and functionality. Today‚ manual override systems are sophisticated‚ incorporating failsafes and protocols to ensure seamless transitions between automated and manual operations‚ reflecting a blend of historical necessity and modern innovation.

1.3 Importance in Modern Systems

Manual override is indispensable in modern systems‚ ensuring safety‚ reliability‚ and adaptability. It allows human intervention during emergencies‚ system failures‚ or unexpected events‚ preventing potential disasters. In industries like aerospace‚ automotive‚ and manufacturing‚ manual override provides a critical fallback‚ ensuring operational continuity. Its importance lies in balancing automation with human judgment‚ enabling precise control when automated systems fall short. This duality enhances overall system resilience‚ making manual override a cornerstone of modern technological design and operation.

Applications of Manual Override

Manual override is widely used in industrial automation‚ aviation‚ automotive‚ robotics‚ and manufacturing. It allows human intervention for precise control‚ safety‚ and efficiency in critical systems.

2.1 Industrial Automation

Manual override is essential in industrial automation for ensuring safety and efficiency. It allows operators to take control of automated machinery during emergencies or malfunctions‚ preventing accidents. This feature is particularly critical in manufacturing and production lines‚ where precise control is necessary. By enabling human intervention‚ manual override acts as a backup mechanism‚ ensuring continuous operations and reducing downtime. Its implementation is vital for maintaining productivity and safety standards in industrial settings.

2.2 Aviation Systems

Manual override in aviation systems is a critical feature that allows pilots to take control from automated systems during emergencies or malfunctions. This ensures safety and precision‚ particularly in autopilot or auto-throttle modes. By enabling human intervention‚ manual override prevents potential accidents and maintains flight stability. Its implementation is vital for addressing system failures and ensuring pilot authority over aircraft operations‚ making it a cornerstone of aviation safety protocols.

2.3 Automotive Control Systems

Manual override in automotive systems provides drivers with the ability to bypass automated controls‚ ensuring safety and control. This feature is essential in advanced driver-assistance systems like adaptive cruise control or lane-keeping assist. By allowing human intervention‚ manual override prevents system errors and enhances driver confidence. It is particularly crucial in emergencies or unexpected situations‚ where immediate control is necessary to avoid accidents‚ making it a vital component of modern automotive safety and reliability.

2.4 Robotics and Manufacturing

Manual override in robotics and manufacturing ensures safety and precision by allowing human intervention in automated systems. It enables operators to halt or adjust production processes‚ preventing errors or damage. This feature is critical in complex assembly lines‚ where unexpected issues may arise. By providing a manual control option‚ manufacturers can address malfunctions promptly‚ maintaining efficiency and product quality. Manual override enhances system reliability and adaptability‚ ensuring seamless integration of human expertise with automated workflows in industrial settings.

Technical Aspects of Manual Override

Manual override involves mechanisms‚ circuitry‚ and integration protocols to ensure seamless human intervention in automated systems‚ enhancing reliability and operational control when needed.

3.1 Mechanisms and Circuitry

Manual override mechanisms rely on physical or electronic circuitry to bypass automated controls. These systems often include switches‚ relays‚ and sensors designed to transfer control to human operators seamlessly. Circuitry may involve integrated components that detect manual interventions and prioritize them over automated signals‚ ensuring instantaneous response during critical situations. Such mechanisms are essential for maintaining operational safety and efficiency in various applications‚ from industrial machinery to consumer electronics.

3.2 Integration with Automated Systems

Manual override systems are designed to integrate seamlessly with automated controls‚ ensuring smooth transitions during human intervention. These systems often employ priority mechanisms‚ where manual inputs override automated signals. Integration involves synchronization of sensors‚ actuators‚ and control units to maintain operational continuity. In industrial automation‚ this ensures production consistency‚ while in aviation‚ it enhances safety by allowing pilots to take control instantly. Proper integration is critical for reliability and efficiency across all applications.

3.3 Protocols for Manual Intervention

Protocols for manual intervention ensure safe and effective transitions from automated to manual control. These include predefined procedures‚ role-based access‚ and emergency activation methods. For example‚ technicians may use specific tools or APIs to override automated systems‚ while pilots can disengage autopilot with control inputs. Clear guidelines minimize risks during manual takeover‚ ensuring operational continuity and safety. These protocols are critical in maintaining system reliability and human safety across various applications.

3.4 Safety Features

Manual override systems incorporate essential safety features to prevent accidents and ensure operational integrity. These include fail-safe mechanisms‚ emergency cutoffs‚ and authorization protocols. For instance‚ manual overrides in industrial machinery often require multi-step authentication to prevent unintended activation. Additionally‚ safety interlocks ensure systems cannot bypass critical safeguards. These features minimize risks during manual interventions‚ protecting both operators and equipment from potential hazards. They are designed to maintain reliability while allowing human control in critical situations.

Safety and Risks

Manual override systems balance convenience with risks‚ requiring careful implementation to avoid accidents. Potential hazards include system malfunctions‚ human error‚ and unauthorized access‚ emphasizing the need for strict safety protocols and training to mitigate risks effectively.

4.1 Potential Hazards of Manual Override

Manual override systems‚ while crucial‚ pose risks such as unintended malfunctions‚ human error‚ and unauthorized access. These hazards can lead to system failures‚ accidents‚ or even breaches in security. Additionally‚ improper implementation or lack of training may result in incorrect manual interventions‚ exacerbating risks. Therefore‚ robust safety measures‚ including failsafes and strict protocols‚ are essential to mitigate potential hazards and ensure reliable system operation under manual control.

4.2 Human Error Considerations

Human error is a significant risk during manual override operations‚ often due to inadequate training‚ stress‚ or fatigue. Mistakes can lead to system malfunctions‚ safety breaches‚ or equipment damage. For instance‚ incorrect manual interventions in automated systems may override vital safeguards‚ causing unintended consequences. Proper training and clear protocols are essential to minimize such risks‚ ensuring operators understand the implications of manual actions and can execute them safely and effectively.

4.3 Emergency Procedures

Emergency procedures involving manual override require swift‚ precise actions to ensure safety and system stability. Trained personnel must follow predefined protocols‚ bypassing automated controls when necessary. For example‚ in industrial settings‚ technicians may manually shut down machinery to prevent accidents. Clear communication and adherence to safety guidelines are critical to avoid further complications. Emergency manual overrides are often last-resort measures‚ emphasizing the need for calm and skilled intervention to restore normal operations effectively.

4.4 Risk Mitigation Strategies

Risk mitigation strategies for manual override involve thorough training‚ system testing‚ and clear documentation. Regular drills ensure operators can safely intervene during emergencies. Implementing fail-safes and real-time monitoring reduces error potential. Protocols should outline step-by-step procedures to minimize downtime and hazards. Additionally‚ periodic audits and feedback loops help refine manual override processes‚ enhancing reliability and safety. These measures ensure that manual interventions are both effective and secure‚ reducing overall system risks significantly.

Legal and Ethical Considerations

Manual override systems must comply with regulatory standards‚ ensuring accountability and ethical use. Legal frameworks define operator responsibilities and liability‚ balancing safety with technological advancements responsibly.

5.1 Regulatory Compliance

Regulatory compliance for manual override systems ensures adherence to industry standards‚ legal requirements‚ and safety protocols. These regulations mandate proper design‚ testing‚ and documentation to prevent failures. Compliance verifies that manual overrides function reliably under all conditions‚ minimizing risks and ensuring legal accountability. Non-compliance can result in penalties‚ system shutdowns‚ or legal action. Authorities like ISO‚ FAA‚ and OSHA enforce these standards‚ ensuring ethical and safe implementation of manual override mechanisms across industries.

5.2 Liability Issues

Liability issues arise when manual overrides fail or are misused‚ leading to system malfunctions or accidents. Manufacturers and operators may face legal consequences if overrides do not perform as intended. In industries like aviation and automotive‚ improper implementation can result in significant financial and reputational damage. Legal cases often highlight failures in design or maintenance‚ emphasizing the need for robust protocols and user training to minimize liability risks and ensure accountability. Proper documentation and adherence to safety standards are critical in mitigating these risks.

5.3 Ethical Implications

Manual override systems raise ethical concerns‚ particularly regarding accountability and transparency. Decisions to bypass automation may introduce biases or errors‚ questioning the fairness of human intervention. Ethical dilemmas arise when overrides are used to prioritize efficiency over safety or vice versa. Ensuring accountability for override actions and maintaining trust in automated systems are critical ethical challenges. These issues highlight the need for clear guidelines and ethical frameworks to govern manual interventions responsibly.

5.4 Case Studies

Case studies highlight the critical role of manual override in real-world scenarios. In aviation‚ pilots often manually override autopilot systems during emergencies to maintain control. Similarly‚ in industrial settings‚ operators use manual overrides to halt automated machinery during malfunctions. These examples demonstrate the importance of human intervention in ensuring safety and reliability. They also underscore the need for proper training and protocols to effectively manage manual override situations without compromising system integrity or operational efficiency.

Examples and Case Studies

This section explores real-world applications of manual override across industries. Examples include aerospace systems‚ industrial machinery‚ and automotive controls‚ demonstrating its role in ensuring safety and reliability.

6.1 Manual Override in Aerospace

In aerospace‚ manual override systems are critical for pilot intervention during emergencies. For instance‚ pilots can disengage autopilot to regain control‚ ensuring safety. Additionally‚ manual overrides are used in spacecraft systems to address malfunctions. These mechanisms are designed to enhance reliability and prevent failures. Historical examples include the Space Shuttle’s manual docking system. Such overrides demonstrate the importance of human intervention in high-stakes environments‚ balancing automation with direct control to mitigate risks effectively.

6.2 Industrial Machinery Applications

Manual override systems are integral to industrial machinery‚ enabling operators to bypass automated controls during emergencies or maintenance. For instance‚ production lines often use manual overrides to halt operations or adjust processes. These mechanisms ensure safety and allow human intervention when automated systems fail. Examples include emergency stops and manual mode switches. Such overrides enhance operational reliability‚ preventing accidents and downtime in manufacturing environments.

6.3 Automotive Industry Examples

Manual override systems are critical in automotive applications‚ enabling drivers to regain control from automated systems. For instance‚ in semi-autonomous vehicles‚ drivers can override autopilot functions for safety. Emergency brake overrides and manual gearshifts are common examples. Tesla’s autopilot system allows drivers to take control at any time. Similarly‚ in industrial trucks‚ manual overrides ensure operators can intervene during malfunctions. These mechanisms enhance safety and reliability‚ bridging the gap between automation and human intervention in automotive technologies.

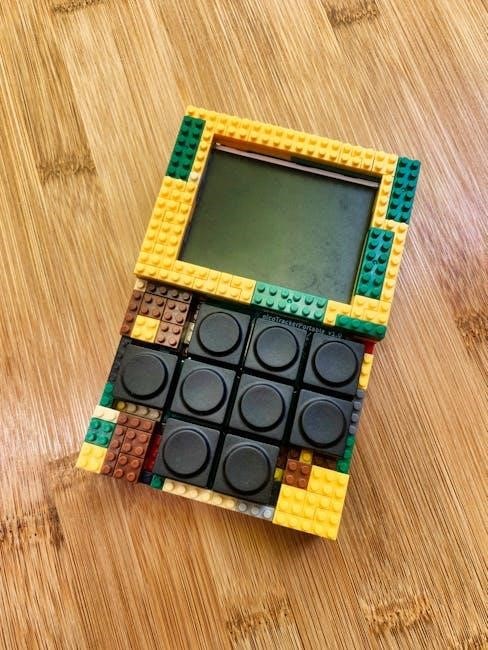

6.4 Consumer Electronics

Manual override in consumer electronics allows users to bypass automated settings‚ ensuring control and customization. Smart home devices‚ like thermostats‚ often feature manual overrides to adjust temperatures beyond preset limits. Security systems enable manual arming or disarming‚ overriding automated schedules. Additionally‚ audio devices may include manual overrides to bypass automatic settings‚ such as EQ or volume limits. These features enhance user flexibility‚ providing direct control when automated functions fall short of meeting specific needs or preferences in daily use.

Human Factors

Manual override effectiveness relies on human factors‚ including training‚ decision-making‚ and stress management. Adequate user understanding and expertise are crucial for safe and efficient system control during interventions.

7.1 Training Requirements

Effective manual override operation demands comprehensive training‚ ensuring users understand system mechanics and protocols. Training should cover emergency procedures‚ decision-making under stress‚ and hands-on practice to build proficiency. Regular drills and updates on system advancements are essential to maintain competence and adaptability. Proper training reduces errors and enhances safety‚ enabling individuals to intervene confidently and efficiently in critical situations‚ such as system malfunctions or unexpected automation failures.

7.2 Decision-Making Processes

Decision-making during manual override involves assessing system conditions‚ evaluating risks‚ and determining the appropriate intervention. Operators must weigh factors like urgency‚ system reliability‚ and potential consequences. Clear protocols guide these decisions‚ ensuring consistency and reducing errors. Training enhances judgment‚ enabling quick‚ accurate actions; Effective communication and situational awareness are critical‚ as manual override decisions often occur under stress or time constraints‚ requiring a balance of expertise and adherence to established procedures.

7.3 Workload Management

Workload management during manual override is critical to ensure operators can handle increased responsibilities. Transitioning from automated to manual control demands focused attention and swift actions. Effective workload distribution among team members prevents overload‚ while clear communication and structured protocols streamline decision-making. Training programs emphasize task prioritization and stress management‚ enabling operators to maintain performance under pressure. Balancing automation reliance with manual intervention ensures operational efficiency without overwhelming personnel‚ fostering a sustainable work environment during critical situations.

7.4 Stress and Fatigue

Manual override situations can induce significant stress and fatigue‚ particularly in high-stakes environments. Operators may experience heightened heart rates and mental tension when taking control from automated systems. Prolonged manual intervention can lead to physical and mental exhaustion‚ impairing decision-making and reaction times. Proper training‚ regular breaks‚ and workload distribution are essential to mitigate these effects‚ ensuring operators remain alert and effective during critical manual override scenarios.

Future Trends

Future trends include integrating AI‚ IoT‚ and predictive maintenance with manual override systems‚ enhancing reliability and efficiency while minimizing human intervention in automated processes.

8.1 Advancements in Automation

Advancements in automation are revolutionizing manual override systems‚ enabling seamless integration with AI-driven technologies. These innovations allow for real-time monitoring‚ predictive analytics‚ and adaptive learning‚ enhancing the precision and efficiency of manual interventions. By incorporating intelligent automation‚ systems can now anticipate and respond to critical scenarios more effectively‚ reducing human error and improving overall performance. This synergy between automation and manual control ensures safer‚ more reliable operations across industries.

8.2 Integration with AI

Integrating manual override with AI enhances system responsiveness and accuracy. AI-driven systems can analyze real-time data to predict failures‚ enabling proactive manual interventions. This fusion allows operators to override automated decisions with informed precision‚ reducing errors. AI also provides adaptive learning‚ improving manual override mechanisms over time. By combining human judgment with AI insights‚ systems achieve optimal performance‚ balancing automation with human oversight for safer‚ more efficient operations across various industries.

8.3 IoT and Remote Control

IoT and remote control technologies enable manual override capabilities to be accessed and managed remotely. This integration allows operators to intervene in automated systems from anywhere‚ ensuring timely responses to critical situations. Remote manual override is particularly valuable in industrial and transportation systems‚ where immediate physical access may not be feasible. IoT-enhanced remote control improves efficiency‚ reduces downtime‚ and enhances safety by enabling swift‚ informed interventions‚ even from a distance. This capability is transformative for modern‚ interconnected systems.

8.4 Predictive Maintenance

Predictive maintenance leverages data analytics and IoT to foresee system failures‚ enabling proactive measures. By integrating manual override capabilities‚ operators can address potential issues before they escalate‚ minimizing downtime. This approach optimizes system performance and reduces reliance on reactive manual interventions. Predictive maintenance ensures smoother transitions between automated and manual control‚ enhancing overall reliability and safety. It aligns with future trends‚ where data-driven insights empower more efficient system management and resource allocation.

Best Practices

Adopting best practices for manual override involves clear design protocols‚ regular training‚ and rigorous testing. Ensure user-friendly interfaces and maintain updated documentation for seamless integration and reliable operation.

9.1 Design Considerations

Designing manual override systems requires careful consideration of user needs‚ ergonomics‚ and accessibility. Ensure intuitive interfaces with clear feedback mechanisms to minimize errors. Incorporate redundancy and fail-safes for reliability. Adhere to industry standards and regulatory requirements. Use robust materials and intuitive controls to enhance usability. Regularly test and refine designs based on user feedback to optimize performance and safety. Prioritize simplicity and consistency in design to ensure seamless integration with existing systems.

9.2 Implementation Guidelines

When implementing manual override systems‚ ensure thorough training for personnel to understand operation and safety protocols. Conduct systematic testing to verify functionality under various scenarios. Integrate overrides seamlessly with automated systems to maintain operational flow. Provide clear documentation and guidelines for manual intervention. Regularly review and update protocols to adapt to system upgrades or changing requirements. Ensure compliance with safety standards and regulatory frameworks to minimize risks and ensure reliability.

9.3 Maintenance and Testing

Regular maintenance is essential to ensure manual override systems function reliably; Schedule periodic inspections and tests to verify system responsiveness and accuracy. Perform functional checks under simulated operational conditions to identify potential issues. Use diagnostic tools to monitor system health and address any malfunctions promptly. Document test results and maintenance activities for future reference and compliance purposes. Ensure all components are calibrated and updated to maintain optimal performance and safety standards.

9.4 User Interface Design

A well-designed user interface for manual override systems is critical for intuitive operation. Ensure controls are clearly labeled and easily accessible‚ with visual cues for system status. Use simple‚ consistent designs to minimize user error. Provide real-time feedback to confirm manual interventions. Incorporate failsafe mechanisms‚ such as confirmation prompts‚ to prevent accidental overrides. Design interfaces to accommodate diverse user needs‚ including accessibility features. Regularly test and refine UI elements to enhance usability and safety in high-pressure situations.

Manual override is a critical feature balancing automation and human control‚ ensuring safety and reliability. Its strategic use in emergencies underscores its importance in modern systems.

10.1 Summary of Key Points

Manual override is a vital mechanism enabling human intervention in automated systems‚ ensuring control and safety. It plays a crucial role in industries like aviation‚ manufacturing‚ and robotics‚ serving as a fail-safe during emergencies. The ability to bypass automated functions underscores its importance in maintaining operational reliability. Training‚ ethical considerations‚ and system design are key factors in its effective use. As technology advances‚ manual override remains essential‚ balancing automation with human oversight.

10.2 Future Outlook

The future of manual override lies in its integration with advanced technologies like AI and IoT‚ enabling smarter systems. As automation evolves‚ manual override will remain a critical failsafe‚ ensuring human control in complex scenarios. Innovations in user interface design and predictive maintenance will enhance its reliability. Training and ethical frameworks will play a pivotal role in balancing automation with manual intervention‚ ensuring safety and efficiency in future applications.

10.3 Final Thoughts

Manual override remains a vital component in modern systems‚ balancing automation with human oversight. Its role in safety‚ reliability‚ and adaptability ensures its continued relevance. As technology advances‚ the integration of manual override with AI and IoT will enhance its effectiveness. Proper training‚ ethical considerations‚ and robust design will be essential to maximize its benefits. Ultimately‚ manual override serves as a cornerstone of system resilience‚ bridging the gap between automation and human intervention for optimal outcomes.